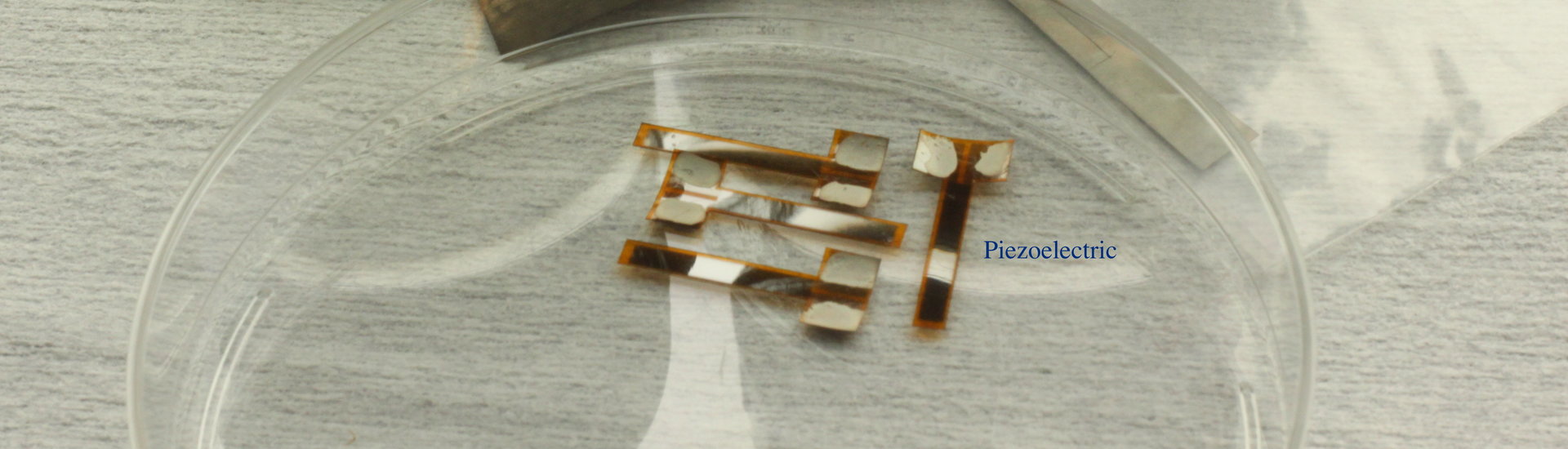

Compliant mechatronic systems with high numbers of individual transducer elements could be useful for various complex distributed sensing and/or actuation tasks in industry (e.g. handling fragile silicon wafers), military (e.g. compliant robots) and medicine (e.g. drug-delivery). Often such systems are impractical to implement due to high total cost of laborious engineering, numerous components and time-consuming assembly process. To a significant extent these limitations can be overcome by using distributed (‘smart’ material) transducers instead of the conventional ones. Entire mechatronic systems can be realized by etching its individual transducers and components into a monolithic ‘smart’ material substrate. However, the today’s ‘smart’ materials also come with their challenges, both in actuation and sensing phenomena. Frequently the smart materials are proposed for application where conventional transducers significantly outperform them, while no attention is paid to distributed mechatronic systems that are difficult to design, construct and miniaturize with conventional transducers.

This work studies and compares sensing and actuation techniques of different smart material transducers in order to overcome the limitations of individual transducers or techniques by combining multiple of them to complement each other.

PI (team)

Hassan Hossein Nia

TU DelftPhD / PostDoc

Wan Hasbullah Mohd Isa

PhD candidate, TU Delft