Technologies

Hydrogen combustion

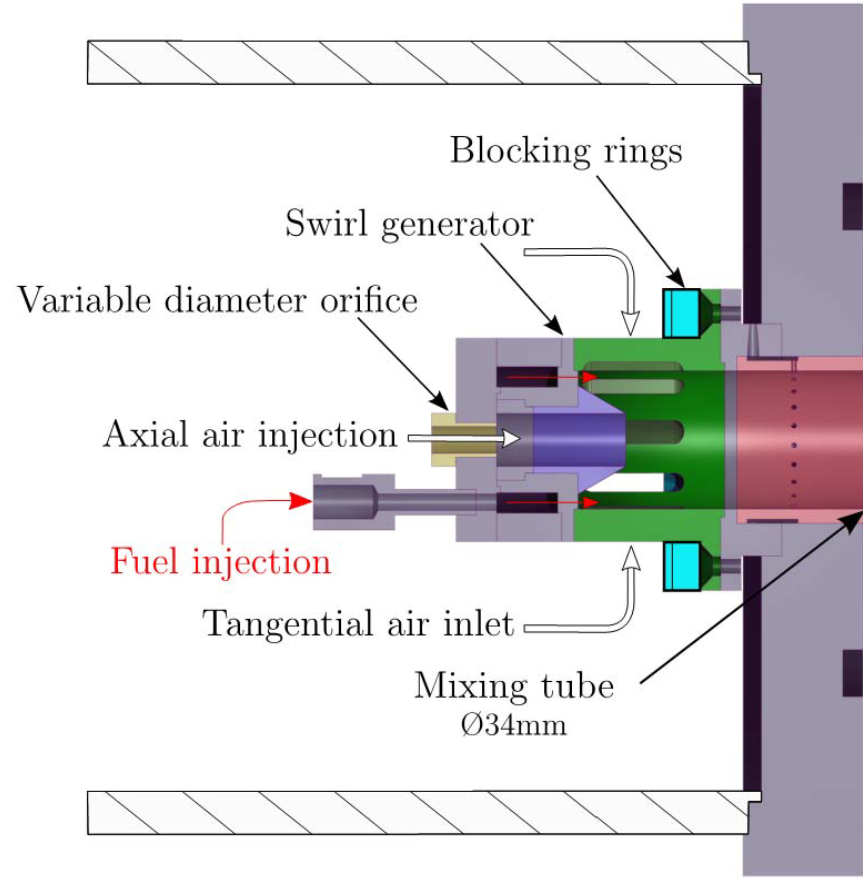

To enable the fuel transition, the APPU system will have a the capacity to operate on either kerosene or hydrogen, depending on the local fuel availability. However, the fuel and combustion properties of hydrogen are quite different from other hydrocarbon fuels. This requires a different philosophy of designing combustors. There have been different combustor types proposed for H2 combustion, like the micro-mixing concept [1][2], lean direct injection [3,4] and swirl stabilized with axial injection [5][6]. While each of the concepts has its own advantages and disadvantages, none of the combustors is capable of handling more than one type of fuel. The swirl stabilized burner with axial air injection will be explored and modified further in the APPU project to be able to burn both H2 or kerosene. There are several advantages of this burner compared to other burners described above:

- The burner geometry is simpler

- The number of fuel injectors is less compared to other concepts

- The burner was successfully tested within the AHEAD project to burn on methane

To allow the burner to run on both hydrogen and kerosene, the swirl stabilized burner with axial injection will be modified in the following ways:

- Incorporation of spray nozzle for kerosene

- Boundary layer blowing for prevention of flashback through the liquid film in the pre-mixing tube

- Convergent exit section of the premixed gas in order to provide a favourable pressure gradient to the premixed air-fuel mixer.

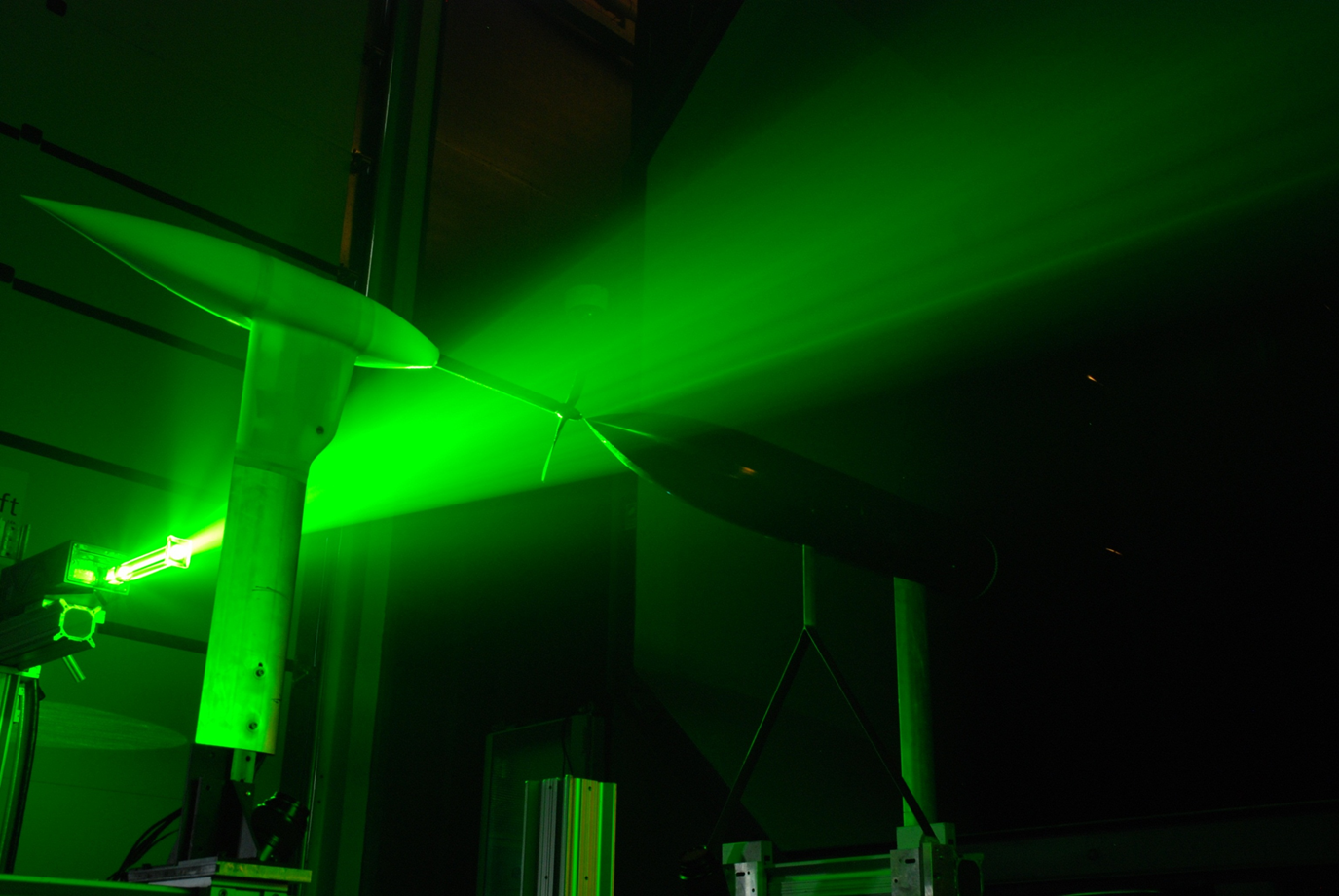

The proposed modifications will be analysed by numerical simulation to investigate the effect of geometrical parameters on the fuel-air mixing and the pressure-gradients within the boundary layer in order to check the flash-back propensity of the design. The modified combustor will be tested experimentally in the combustion lab of TU Delft.

Boundary Layer Ingestion

One of the main technological pathways adopted engine manufacturers to reduce engine fuel consumption is the increase in the engine bypass ratio (BPR). However, there are several challenges that must be overcome when increasing the BPR further, such as an increase in engine and nacelle weight, increase in nacelle & installation drag, smaller ground clearance and adverse effect on aircraft stability. Nevertheless, instead of aiming at higher BPR, other techniques for increasing the engine propulsive efficiency are available such as Boundary layer ingestion (BLI). The BLI is a novel aircraft engine integration technique which can offer several benefits [7][8][9] as listed below :

- Reduction of velocity deficit in the aircraft wake as well as a reduction in the propulsor wake, thereby reducing aircraft drag and also increasing the propulsive efficiency.

- Aircraft level benefits include possible total weight and drag reduction due to the smaller / integrated nacelles.

- Smaller yaw control surfaces and vertical stabilizers due to closer spacing of propulsor and fuselage symmetry plane.

However incorporating BLI in an actual aircraft requires substantial changes in the aircraft architecture and associated propulsion systems, as has been shown by the previous studies [21][22][23]. These requirements complicate the implementation of BLI in an aircraft in the near future. In the APPU project, the aforementioned challenges of incorporating BLI in the aircraft design will be avoided since:

- The BLI propulsor will be mechanically powered by the APPU, removing the need for additional sub-systems that introduce weight and efficiency penalties

- Open-rotor design. Not including a nacelle or propeller shrouding will reduce weight and drag.

By not including a shrouding of the propeller, the noise of the BLI propulsor is not shielded and could potentially increase the aircraft noise level. However, by careful design (i.e. lower disc loading) and optimization of the BLI propeller and the empennage (i.e. wake blowing), these challenges should be addressed.