Tagging concrete aggregates for circularity

Themes: Materials, Structural Engineering

A TRL is a measure to indicate the matureness of a developing technology. When an innovative idea is discovered it is often not directly suitable for application. Usually such novel idea is subjected to further experimentation, testing and prototyping before it can be implemented. The image below shows how to read TRL’s to categorise the innovative ideas.

Summary of the project

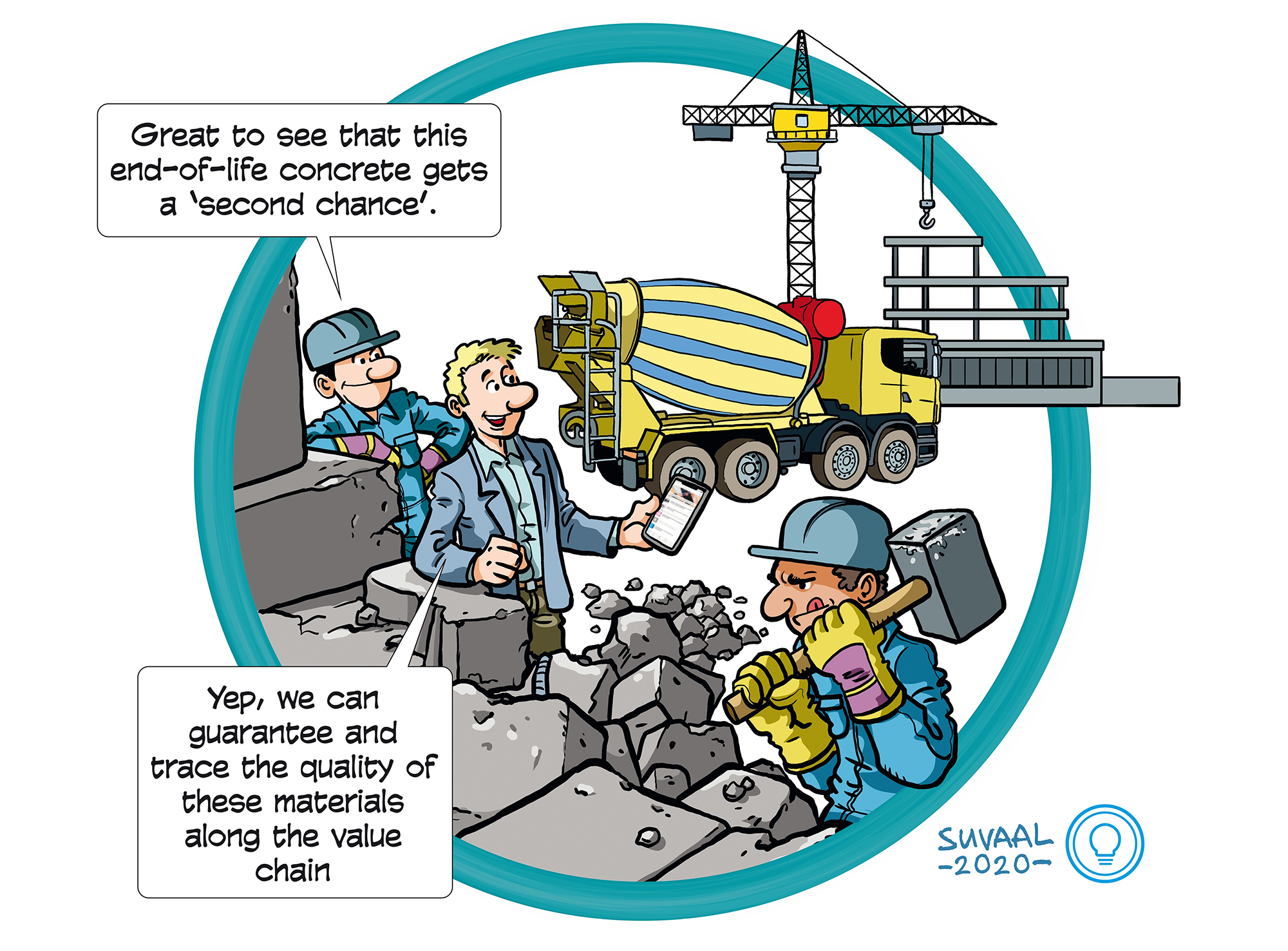

The main target of the researchers is to make the use of concrete circular. In order to do this, you need to develop not only innovative technologies that can break down and separate concrete waste into its various components (e.g., aggregates and minerals) but also make sure that the product satisfies consumer needs by explicitly displaying the quality of the product (recycled aggregates). To effectively achieve circularity, it is essential to provide the customer with the guarantee that what they buy is what they get. Therefore, the researchers of the R&R group designed/developed a process through which the quality of the aggregate can be traced throughout the value chain.

During the separation process of concrete waste, the quality of the aggregate is monitored by storing full information of the product in RFID tags that can be accessed through an online platform. The tags are mixed with the aggregates and eventually are embedded in the new concrete being produced. The tags and the platform contains information of the particle size distribution, composition, quantity of contaminants(if any), and other characteristics of the substrate for a batch of recycled concrete. Additional information that is stored on the platform refers to the parties involved in the supply chain (e.g., details of the demolition project- who did what, and the location). Companies interested in reusing concrete aggregates can access the platform to determine which batch they want to buy based on the listed specs.

The innovative idea is that each ton of recycled aggregate is tagged by mixing in a small information carrier tags that stores the same information as the platform. By tracing and reading the tags, the customers can check if what was delivered is what they wanted. The tags are selected to not affect the properties of the newly produced concrete and, in the end, can also be traced in the new construction. Furthermore, with the available information on the quality of the aggregate, it is possible to match the needed quality requirement for your construction with the matching quality of the aggregates. This extends the choice of how the materials are being used to diversifying resource flows. Thus, when you want to make a lower-end product, you could choose to use aggregates that properly match it, whereas, for high-end use of concrete, you could choose to use higher quality recycled aggregates or opt for using the virgin materials for concrete.

What's next?

Currently, this new technology is being validated in a large EU project. The next step for the tracing and tagging of aggregates is for the construction sector to implement this technology in their way of working so it can become standard practice to buy and use certified recycled materials. Another additional next step could also be to provide customers with advice on how to optimize the use of the recycled aggregate based on its quality properties.

Dr. Francesco Di Maio

dr. Abraham Gebremariam

Ali Vahidi MSc

Prof. dr. Peter Rem

Faculties involved

- CEG