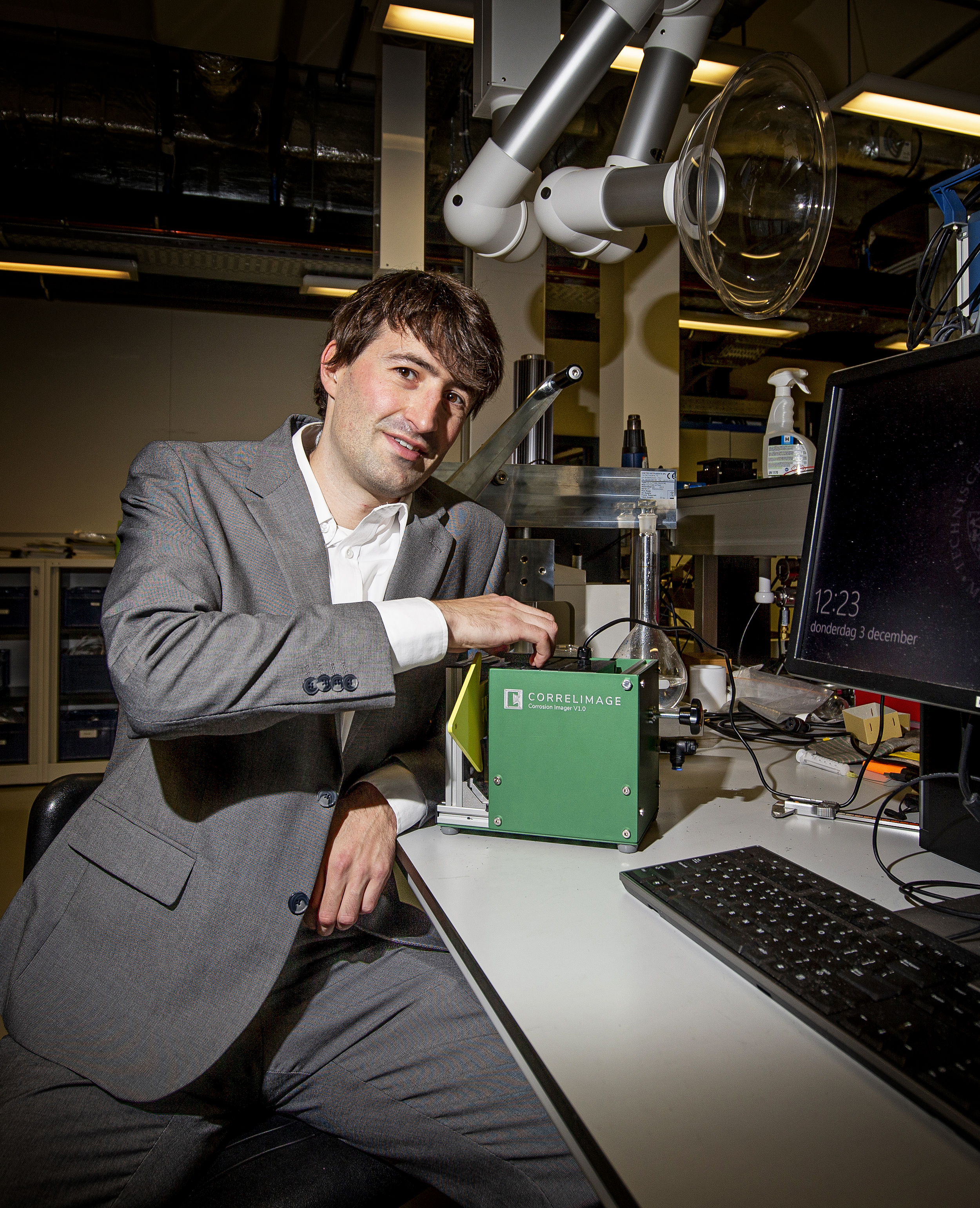

Corrosion is a plague to aviation and countless other sectors worldwide. Paul Denissen is literally targeting this phenomenon: with his ‘Corrosion Imager’ he can display the presence of corrosion in high resolution and real-time. A giant step forward in tackling corrosion. It’s also an inspiring example of how doctoral research can lead to a rock-solid start-up, in this case Correlimage.

I really thought that corrosion was the least interesting topic I could choose for my study of materials science before I started my PhD’, the young scientist laughs. ‘But I found the idea of developing and applying new coatings and measuring techniques really intriguing. My broad interest in materials science and my knowledge of it was the perfect match for corrosion. The further I delved into the subject matter, the more fascinating it became - especially because there’s so much that’s still unclear about corrosion and how to prevent it

Paul Denissen

Bulls-eye

To solve the corrosion puzzle, Denissen had to unearth its source. To do this, he developed a special microscope set-up, capable of observing the smallest changes occurring in materials during corrosion in real time. The innovation turned out to be a bull’s-eye for his research. In October 2020 he obtained his PhD in In-situ visual quantification of corrosion and corrosion protection at the Novel Aerospace Materials research group, at the faculty of Aerospace Engineering TU Delft. What’s more, his research setup proved to be of great value to a specific target group.

People frequently approached him at conferences to ask if his setup was for sale. But the motivation to seriously consider this only ignited when a company in metal surface processing showed serious interest (spring 2019). ‘Several tests later, it turned out that the method really did offer ample potential. The set-up accelerated the control process that this company uses to check that their protective layer on fences works properly, for instance. On the advice of the Innovation & Impact Centre of TU Delft and with financial support from the NWO, we applied for and conducted a feasibility study’.

A period of intensive consultation with paint and coating companies followed. ‘We also attended some programmes at Yes! Delft, the ideal place if you want guidance in your start-up. After a market study we came to the conclusion that Correlimage can be of great value for a small, specific market. Besides myself, our team consists of Dr Santiago Garcia (Associate Professor at the Faculty of Aerospace Engineering), Frank van Doesum (Customer validation) and two software programmers. Our main product is the Corrosion Imager’.

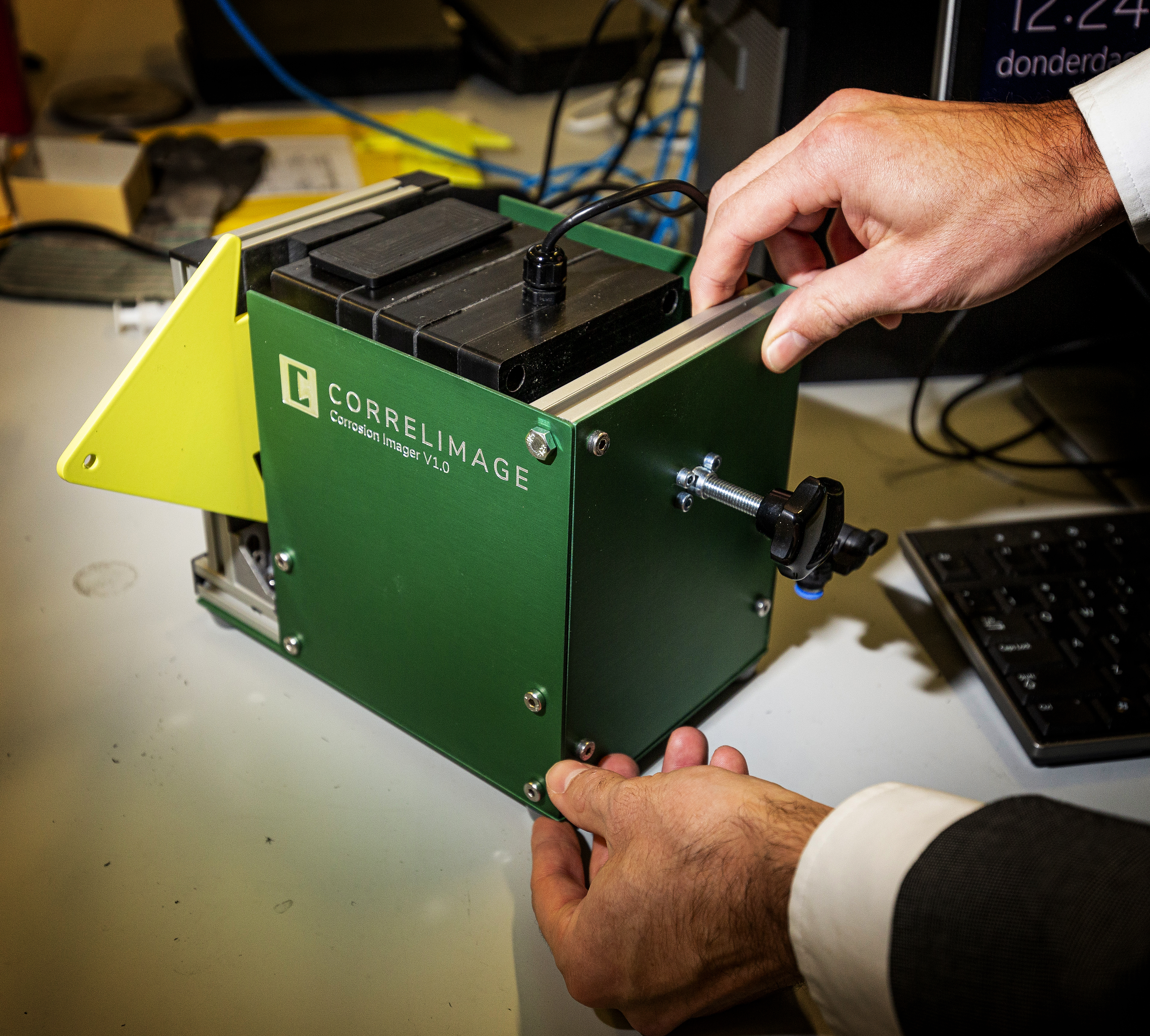

The software package of the Corrosion Imager that quantifies the corrosion processes on high resolution and in real-time.

Inspection with image recognition

Researchers can use the Corrosion Imager to develop their next generation coatings and surface treatments. Using image recognition software, the setup can accurately assess degradation on metals, coatings and other surface treatments while the protection or degradation process is still ongoing. Denissen: “You can see this as a type of Machine Learning.” The Corrosion Imager provides objective and quantifiable image material that's ideally suited for the latest artificial intelligence techniques. ‘This is why our main target group comprises research groups and companies around the world that are constantly on the lookout for the best ways to develop new coatings or corrosion protection agents’.

However, the company’s horizon extends beyond this: ‘Image recognition and smart optical methods are the solution for replacing and improving current manual inspections, enabling better prediction of material longevity. In the near future, for example, our technology could be useful for the development of batteries and solar panels. The process involved in corrosion, batteries and solar cells is very similar in terms of research methods. That’s why we’re looking at a lot more applications than just coatings’.

Hurdles

The biggest hurdle Denissen is currently facing is the huge gap between science and industry. ‘Techniques that we develop at the university and use for research often don’t fit in well with what the business community expects’. This means that a lot of applications, especially for coatings and anti-corrosion agents, can’t be marketed directly. This is also the case with the Corrosion Imager at the moment. The industry often uses different standards, which hinder scientific innovation. This makes it difficult to create a good market for a new product’.

So, there’s a long way to go. ‘We recently conducted a market study that highlighted these hurdles. For the Corrosion Imager, we can already help a lot of scientists working in research and there are good prospects for developing the method further for a broader market. That’s the path we’ve mapped out’. In addition to the aforementioned support troops, the entrepreneur has received plenty of support from the startup voucher programme of the Aerospace Innovation Hub and the accelerator programme of the European Innovation and Technology Institute for Raw Materials (EIT-RM) with coaching and financial support.

First paying customers

Meanwhile, they’ve found the first paying customers for the initial pilot of the Corrosion Imager: ‘When we emailed researchers in our field about our activities, responses flooded in, including a research group in England, comprising a university and science institute. They wanted to participate in the test phase and purchased the prototype knowing that they were the first to apply this new technique and that they would be included in the further development of the Corrosion Imager’.

The main objective is to share the technology. ‘I did some research and wrote a nice dissertation and articles. What I want to do now is to use Correlimage to create a beautiful, affordable product that also benefits others’. When it comes to his own field of expertise, the scientist hopes that the Corrosion Imager will accelerate the development of various corrosion processes or batteries. ‘That less investigation is needed for the end result, thanks to the image recognition in the method - which, by the way, is taking off everywhere’.

Denissen hopes his success will inspire other researchers and young entrepreneurs: ‘If you’ve got a good idea, it’s certainly worth launching a start-up. It gives you so many valuable insights into starting a business! And there are so many facilities available to make your idea a reality, even if it’s on a small scale. The ideal always seems to be the start-up that explodes into a multi-million dollar company, like Swapfiets. But solving a problem for a specific target group is no less valuable’.