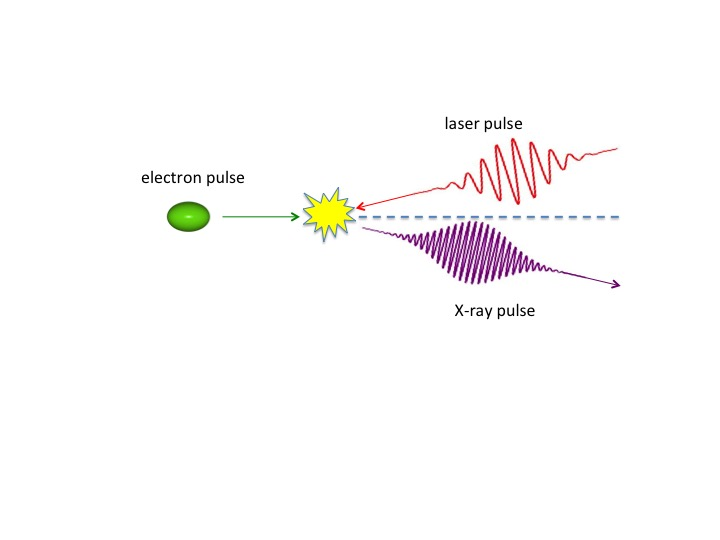

Synchrotron facilities X-ray technology is used in a multitude of industrial, academic and medical applications, ranging from pipeline inspection to the investigation of historical paintings. This is typically done with conventional X-ray sources, which however have limited intensity and tunability. More advanced applications, such as the development of high-tech materials and of new pharmaceuticals, require high-intensity radiation with high coherence and tunable photon energy. Currently, such radiation can only be generated in synchrotrons - large accelerator facilities. All existing synchrotrons are located outside the Benelux region, while the high demand for beamtime puts severe restrictions on availability. Inverse Compton Scattering Using new accelerator technology, a compact and highly flexible setup will be built, in which accelerated electrons convert laser light into an intense and coherent X-ray beam through the physical process of Inverse Compton Scattering. With this radiation, state-of-the-art analyses can be performed in the abovementioned fields of application, thus meeting the demands of society in a variety of ways. Although the specifications of the novel X-ray source, dubbed Smart*Light, will not be equal to those of the current synchrotron facilities, the compact design and high degree of flexibility will make it highly complementary. As such, users will be less dependent on the limited beamtime at synchrotron facilities. Microstructure of materials and hidden layers underneath paintings The instrument will consist of an X-ray source and two detector systems. It will be highly compact (under 4 meters) and can therefore be set up at any research facility. This will allow for complex measurement configurations and long-term experiments. These will be of key value to assess the relationship between process conditions, microstructure and properties for a variety of materials, such as steel, metal alloys, 3D printed materials, etc. On the longer term, Smart*Light offers potential for medical imaging in hospitals, and for studying the authenticity and degradation processes of valuable artworks. The instrument can also contribute to revealing hidden layers underneath existing paintings. Collaboration Netherlands-Flanders In the Smart*Light project, universities, companies, museums and research institutes with a wide range of expertise work in close collaboration. The X-ray source will be designed and built at TU Eindhoven, while the Universities of Ghent and Antwerp will develop detection systems that are tailored to the characteristics of the source. TU Delft will demonstrate the functionality of Smart*Light for materials research, with a focus on engineering materials (steels, metal alloys, coatings) and materials for arts and archeology. Other members of the consortium are VDL ETG BV, Agfa Healthcare, Erasmus MC, Stichting tot Beheer Museum Boijmans van Beuningen, TI-COAST, XRE NV, Koninklijk Museum voor Schone Kunsten Antwerpen and Stichting Materials Innovation Institute. TU Delft (Department MSE of faculty ME) is the project coordinator of Smart*Light. Contacts TU Delft: Dr. Hessel Castricum, project manger |