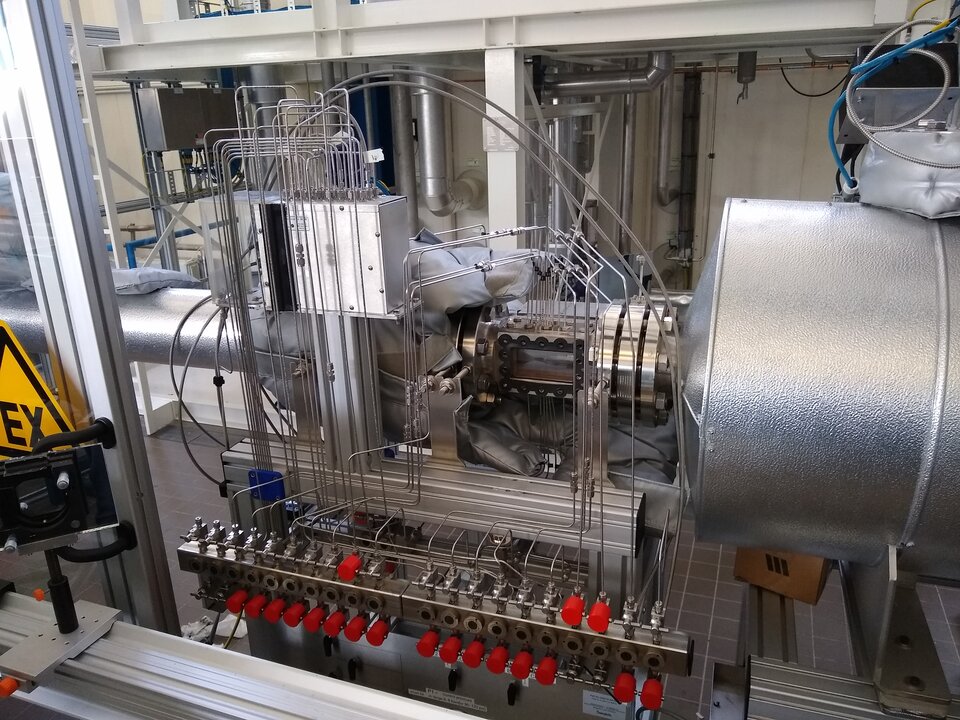

The Water Phantom setup with Electrometer was delivered and tested by DEMO at Holland PTC. This setup allows the intensity of a proton beam to be measured at various positions within a water tank.

The proton beam at Holland PTC is used for tumor treatment and scientific research. The advantage of proton therapy is that the energy is only released at a specific depth. Additionally, the beam can be deflected with magnets and narrowed with collimators, making it possible to target a specific volume very precisely.

This setup is specially developed for the beam used in eye treatments. By performing the measurements in water, the effects on other tissues can be easily calculated, which is why a water tank was chosen. Measurements are taken with two ionization chambers: one in the water and one directly in front of the tank. The sensor outside the tank corrects for variations in beam intensity during a scan.

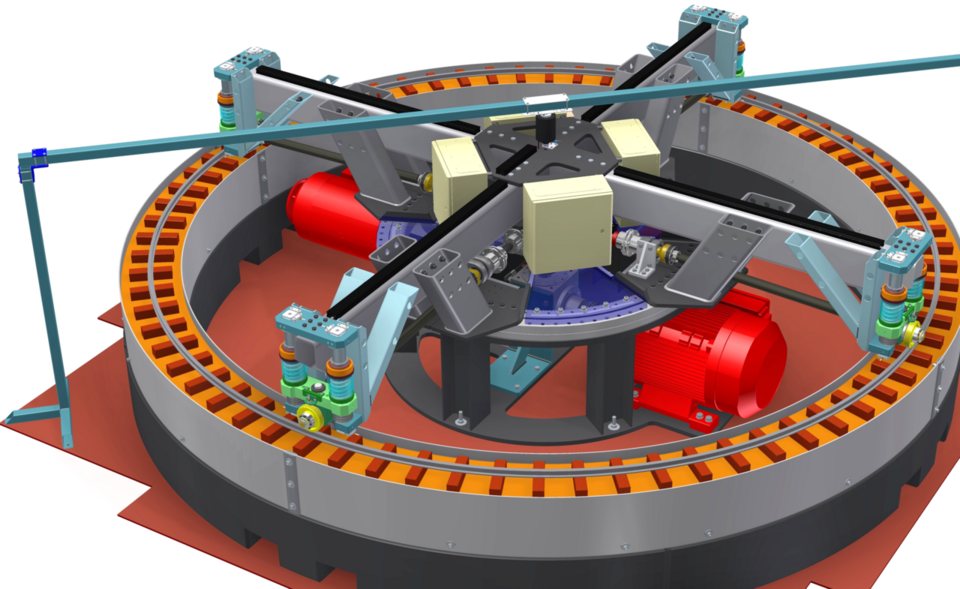

The PMMA water tank, specifically designed by DEMO for this setup, has a thin wall on the side where the beam enters to minimize impact on the measurement. The mechanical design of the Water Phantom, including the drive and structure for positioning within the treatment room, was carefully developed.

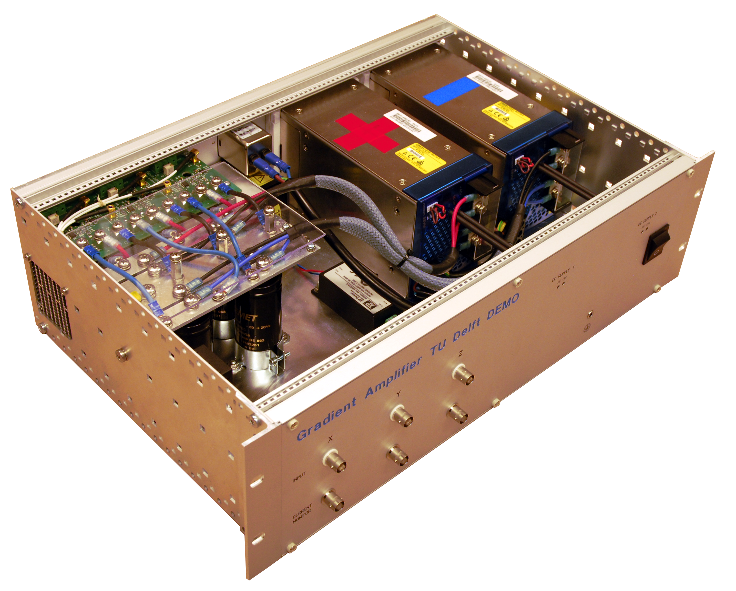

In the photo, the Electrometer is shown, which supplies the required high voltage for the ionization chambers and can measure the very small charge generated. During a measurement, the Electrometer moves the sensor in the water to the next position until the scan is complete.

The assembly of the electronics was meticulously carried out by DEMO, as the current to be measured is less than 1 [pA] at a bias voltage of 400 [V]. This is only possible if the PCB is extremely clean and well shielded. For instance, the input of the measurement amplifier must never be touched by hand to avoid contamination.

The PC software for executing, storing, and live-tracking scans, as well as most of the FPGA work, was specifically developed to process a measurement from both channels every microsecond. Finally, the electronics and software within the device itself were designed and programmed to precisely support measurement performance.