Experiments in the J lab

Fuel cell innovations, energy storage and conversion, and the production and use of biofuels are key to a successful energy transition. The J lab, the experimentation hall at Process & Energy, has everything researchers need to scale up from a good idea to a full-sized process technology installation.

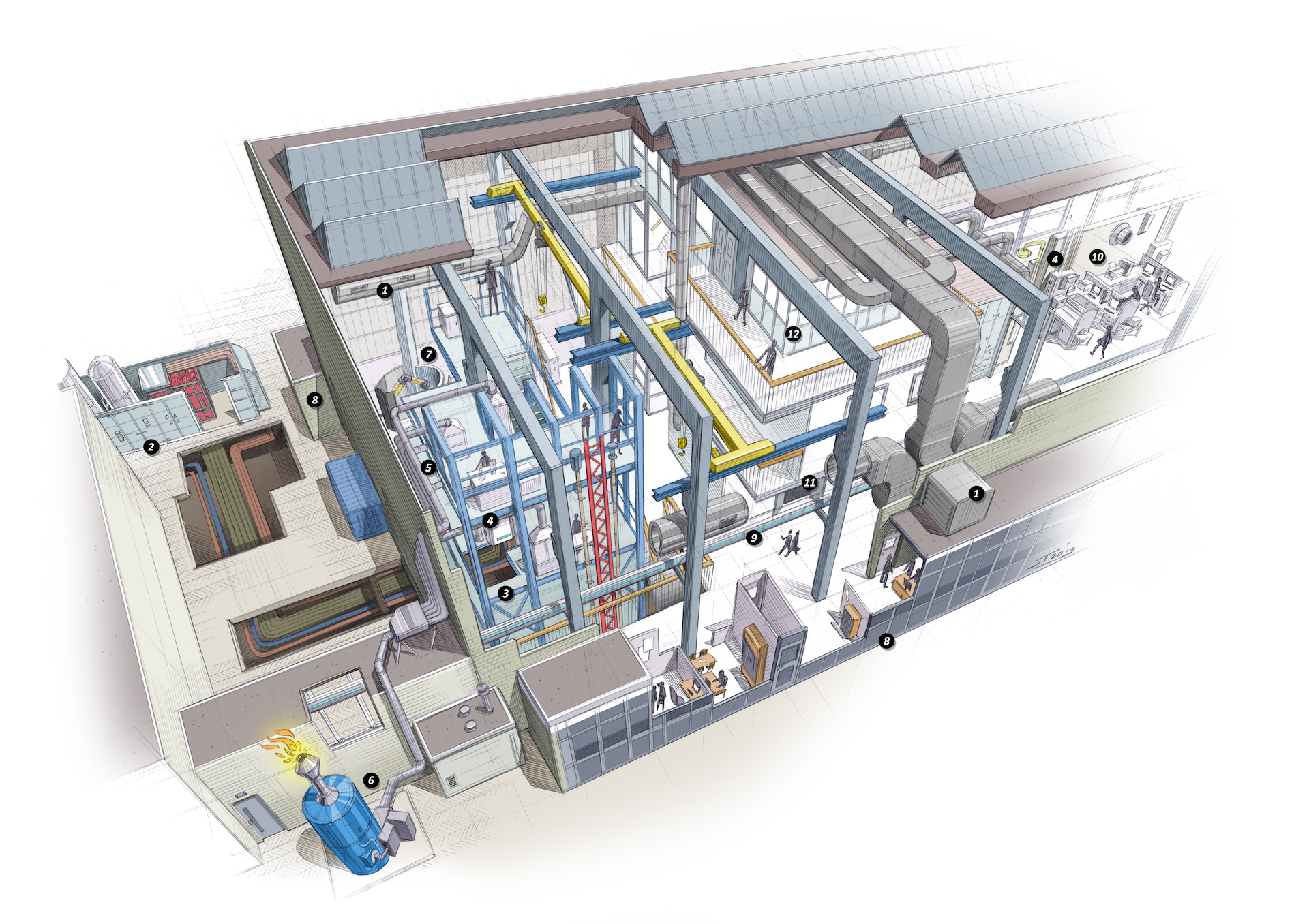

A prominent blue steel construction, which users call ‘the frame’, takes up almost half of the hall and provides 300m2 of space for experimental installations that are too big for the lab and not yet mature enough for a pilot plant. Most of the other half of the hall is given over to lab areas that support these scaled-up experiments. Small-scale research work is

also carried out here.

The interfaculty Negative Emissions Programme, which focuses on the removal of greenhouse gases from the atmosphere and on large-scale energy storage, is conducting lots of experiments in the hall. There is also a wide variety of installations – from research into generating energy from temperature variations in the ocean, to generating electricity by gasifying human waste into plasma.

Illustration: Stephan Timmers

1. Ventilation – Large ventilation tubes provide the hall with fresh air and maintain a constant negative pressure so that hazardous gases cannot escape to the outside.

2. Central gas storage – Tanks containing liquid nitrogen, argon and carbon dioxide. Gas cylinders containing oxygen, hydrogen, carbon monoxide, methane, helium and ammonia. There is also a liquid nitrogen decanting point.

3. Basement – Loops underneath the entire hall to supply gases, electricity, and softened, demineralised and drinking water. With branches leading off to the more than twenty media panels in the frame and labs.

4. Media panels – Provide connection points for gases, compressed air, water, electricity and data. Here the gas pressure is lowered to the desired level for the experiment.

5. Gas outlet pipes – Incorporated into the structure of the experimental tower for the removal of carbon monoxide and hydrogen released during experiments. Electrically heated to 150°C over its entire length to prevent tar deposits, and thus blockages.

6. FLARE – Small chimney pipe with a gas flame at the bottom for flaring the dangerous gases released. Only used if necessary.

7. Workshop – Lathes and workbenches, cutters and a welding shop for metal processing and manufacturing non-commercially available parts. At two locations in the hall.

8. Offices – For building managers and principal investigators. Other researchers are housed at the ME Faculty.

9. Sludge loop – A 140-metre-long folded horizontal tube for research into mixing water and air bubbles.

10. Analytical lab – Fume cupboards, spectrometry, chromatography and other equipment for the analysis of samples (in particular of interim and final products of large installations).

11. Laser labs – Research to promote the deposit of salts by stimulating crystallisation using laser light.

12. Crow's nest – Flexible workspaces for (Master’s) students.