Is it possible to bend glass to a point where it won’t shatter but grow stronger instead? Tim van Driel, MSc student Civil Engineering, became fascinated with building projects involving glass structures during his Bachelor studies. Not surprisingly, he dedicated his final research project to exploring the limits of using glass in facades. He took to the lab and bended large sheets of glass without using heat. But at what point does bending turn into snapping – and a shower of shards?

Tim has been sweeping up glass in the lab a fair number of times in the course of his experiments. But luckily he has also found out quite a lot about cold bending glass and how it can be used as a constructive element in buildings. His predictive model provides an excellent base for further research.

What has driven you to get involved in this research?

I had a discussion with our glass expert professor about possible topics for my thesis. He had started a project at the University of Cambridge, before he taught at the TU Delft, where he did some research and experiments with bachelor students. In this project they looked into bending glass, but instead of heating it to over 400 degrees Celsius and forming it over a mold, they tried doing it cold. I was very interested in the project, because of how innovative and exciting it sounded. Cold bending glass, making use of high-tech ultra-thin glass and being able to do actual experiments in the lab. What’s not to like?

What was your part in this research?

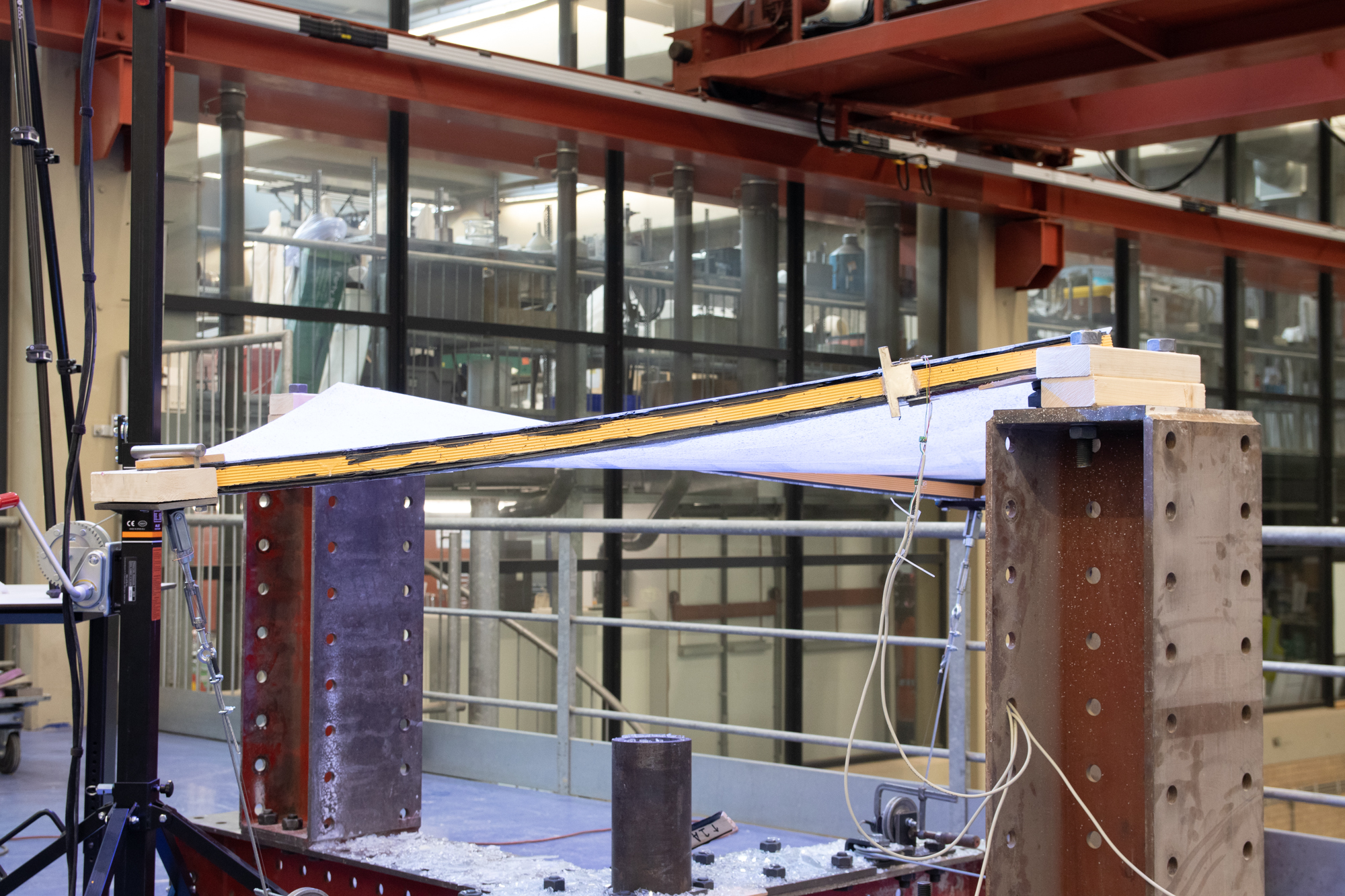

The experiments in Cambridge were done with single glass panels with a frame around the edge. I would expand upon that research by adding a second panel on the other side of the frame, creating a double glazing unit. This is more similar to the real world because everybody is building with double glass nowadays for sustainable reasons.

To investigate how the glass unit would react when bending it, I modelled them into the computer first. This way I could try out and simulate what the glass would do when putting weight on it. To verify the model, I did the same experiments in real life in the Stevinlab at the Civil Engineering faculty.

How does this experience relate to your Civil Engineering Bachelors?

The BSc Civil Engineering was very important for learning the fundamentals of engineering. Learning about materials science, and how to calculate with forces and stresses acting on those materials. It also taught me to think critically and solve problems in an academic fashion, for example approaching and setting up the project in the right way, which is obviously quite important when conducting research.

Which parts of your MSc could you use?

I followed the track Building Engineering in the MSc Civil Engineering. In this track, I gained more practical knowledge about structures, the materials used to build them, and methods to design and perform calculations on them. Thanks to this track, I had knowledge about how glass behaves, how plates behave, and how to set up models in the computer.

What did you look forward to the most?

From the start I’ve been looking forward to the experiments in the lab. Unfortunately Covid-19 caused delays, but when I was finally able to do them it was an amazing experience! It always feels good to have something tangible at the end of a project, because it makes it feel more ‘real’.

What was your biggest challenge?

Remaining focused and working towards the end goal proved to be the biggest challenge. It’s easy to get lost in all the things you can do and different paths you can take. If you’re not careful, you are wasting time on things which turn out not mattering in the end. Sometimes this caused me to lose motivation and focus even more, but that’s just part of the process, and in the end I got through it.

What is the most important thing you learned?

Not surprisingly, the most important thing I learned is related to the biggest challenge I encountered: making an informed choice on all different directions I could go in. It was difficult to find a balance between having a good overview of all the options, and needing the time to investigate all options thoroughly. In the end I tried to weigh the pros and cons of decisions quicker so I could spend more time on the actual research.

What did you enjoy the most?

The process of setting up the experiments was very satisfying for me. Shifting the focus from months of modelling and calculating, to then ordering materials, assembling the panels, tweaking the experimental setup and finally performing the tests was a very cool process.

What will you remember looking back?

I’ll look back fondly on the amount of people willing to help. Teachers and professors taking time to explain something or answer questions, often enthusiastically. Companies providing materials for the experiments. Fellow students willing to discuss your issues and providing support when needed. In a time where everyone is working from home, reaching out for help felt like a larger hurdle than normal, but I found that everyone was happy to help when I asked them.

How will the research continue?

One of the things that would be very useful to do with the knowledge gained is doing a parameter study with the model I’ve made. This means looking at different sizes, different glass thicknesses, different frame materials, etc. This way more insight can be gained into the limits of this type of panel. After that, more tests can be done to look at special circumstances, like wind load for example, to get a better understanding of how the panel behaves.

What are your own plans after this?

Soon after finishing my thesis, I will be starting as a junior structural engineer. Hopefully I will be able to work on some projects where structural glass is used, so I can directly apply the knowledge I have gained during my thesis!