Much of the high-quality waste glass still ends up in landfills because contamination would make it unsuitable for recycling. According to researcher Telesilla Bristogianni, that’s a shame and also unnecessary as it’s perfect for making excellent cast glass building blocks. ‘The glass industry should simply forget its obsession with perfection’.

A few years ago, the Greek PhD candidate, together with her fellow researcher Faidra Oikonomopoulou, made headlines with a façade of glass bricks in the P.C. Hooftstraat in Amsterdam. They helped to replace a 19th-century façade of a store by a completely transparent construction. Tests showed that the cast clinkers of the Crystal House façade were extremely strong.

In principle, it’s also possible to cast them from waste glass. ‘The only problem is that there is not yet sufficient information available about the exact qualities of the material for it to be considered a breakthrough as a building product’, explains Bristogianni. ‘My PhD research makes it clear that cast glass loses almost no strength at all as a result of air bubbles or contamination, which means that it is very suitable for producing building blocks and beams.’

Landfill

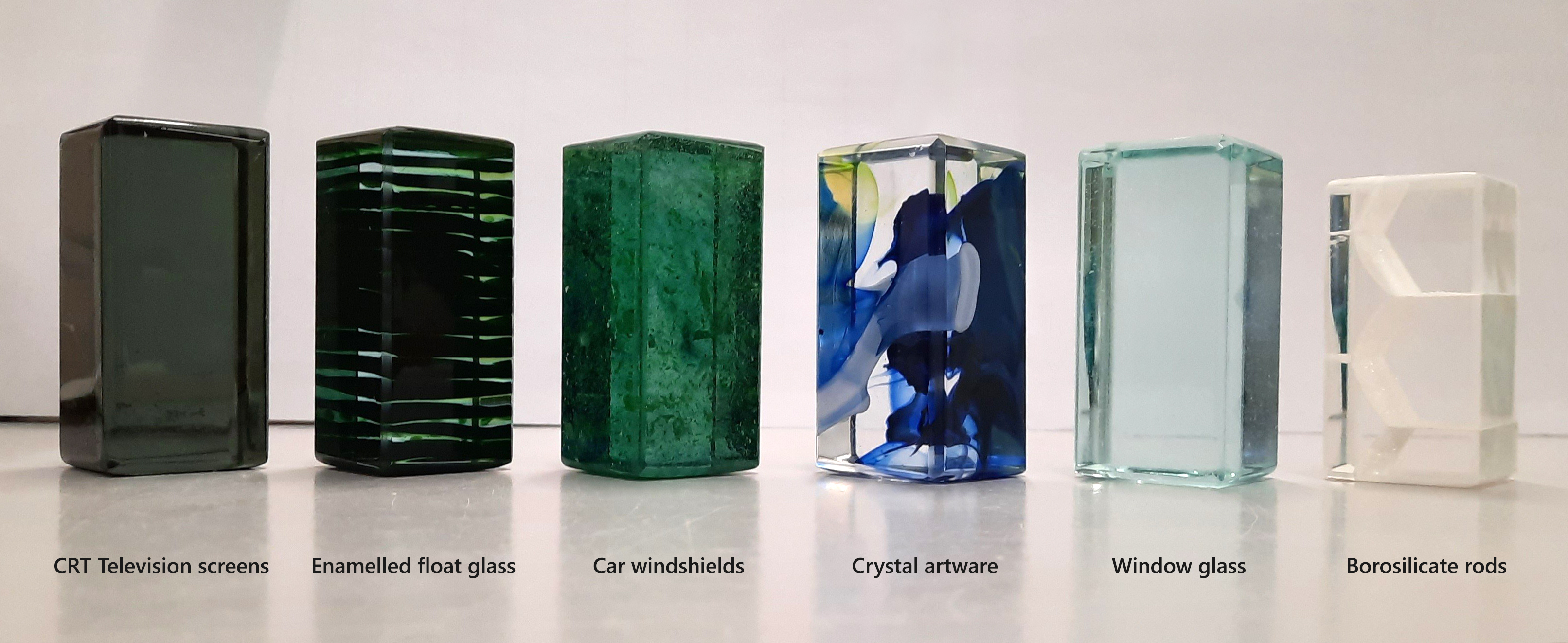

Her research focused primarily on types of glass that, for the most part, still end up in landfills after they have been used. Glass from TV and telephone screens, mirrors, oven dishes, vaccine bottles, coated glass and oven doors contains relatively high levels of contamination and has a different melting temperature than bottle glass for example. That is why glass producers prefer not to use such materials. That is a shame, as remelting and recycling such materials requires on average 300℃ less heat than producing new glass.

Cast glass

In the laboratory of the Faculty of Civil Engineering and Geosciences (CEG), Bristogianni cast thousands of test pieces from waste glass and tested them to determine their bending strength, stiffness, and fracture resistance. Melting took place at relatively low temperatures of 750 to 1120 ℃. The bending strength of cast glass turned out to be particularly high. Some objects reach a strength of 73MPa. The tensile strength is significantly less, and it is therefore important to prevent concentrations of tension when stacking blocks. Glass blocks with curved organic shapes seem to be less susceptible to such issues. That makes it simpler to stack them, even without the use of glue. Her colleague Oikonomopoulou is doing additional research in this area.

The addition of more contamination, for example by mixing in coatings, PVB foil, or small stones that are sometimes found in glass fragments from car windows leads to variations in quality. ‘But with proper engineering, it remains safe for use in cast glass’, explains Bristogianni. ‘Besides, it provides an interesting new material.’

Stained glass 2.0

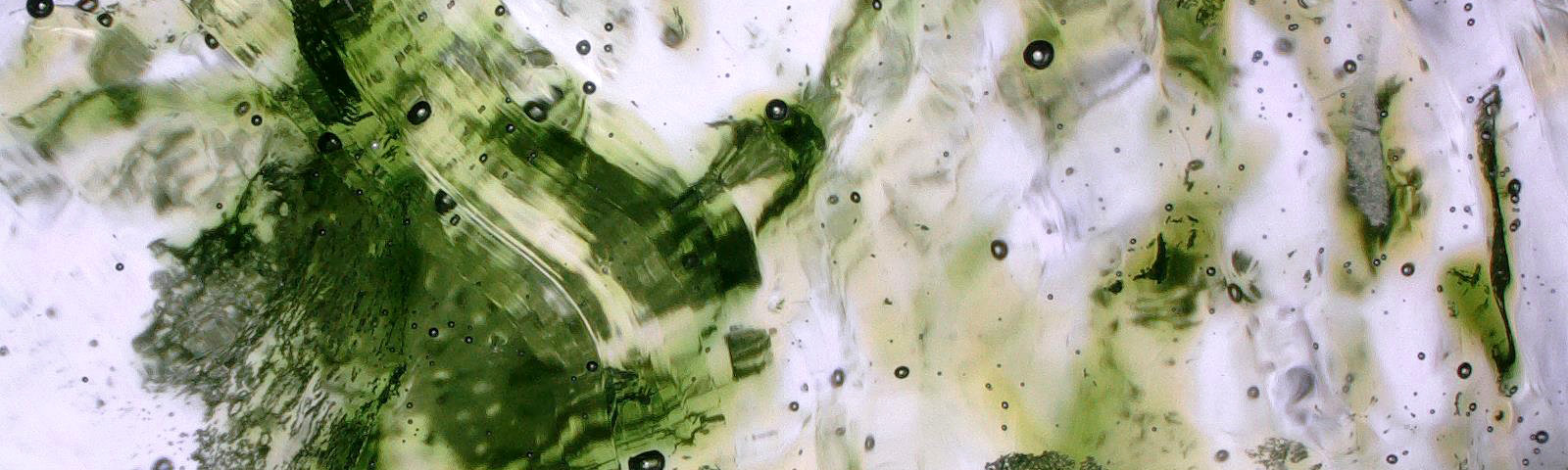

Photographs that she took of the test pieces reveal glass with magical colour patterns. These are caused by contamination in the waste glass as well as the high viscosity while casting. For example, remelted glass made from oven doors provides glass blocks with green strands, whereas remelted safety glass comes out black from the furnace. The patterns are sometimes unpredictable, which is why the industrial sector prefers not to use such products. Nevertheless, the researcher sees ample opportunities to apply this ‘stained glass 2.0’ in architecture. ‘The defects make each of the test pieces unique. If you cannot avoid defects, embrace them’. She also succeeded in making cast glass that was reinforced at critical points by mixing various types of recycled glass.

The dissertation provides an overview of all the defects that occur in blocks of recycled glass. It also lists the measured effects of bending tests and of changes in the chemical composition. Now that these results are available, will architects soon be able to use cast glass as a catalogue product? ‘No, before it can be used as a building material, validation is needed. But the research results do make it clear that it is certainly possible to make a façade from recycled cast glass. That is something I look forward to’.

Published: November 2022

More information

- PhD candidate Bristogianni recently won the ‘Best paper award 2020’ of the Glass Structures & Engineering Journal and the ‘Young Researcher Award 2021’ of the International Journal of Structural Glass and Advanced Materials Research.

- She will defend her dissertation ‘Anatomy of cast glass: The effect of casting parameters on the meso-level structure and macro-level structural performance of cast glass components’ on 25 November. Her promotors are dr. ir Fred Veer and prof. ir Rob Nijsse.

- Read more about the Re3 Glass project here.