Pieter Stoutjesdijk is nominated by the Faculty of Architecture and the Built Environment for the ‘Best TU Delft Graduate’. The fledgling engineer built a house using only a computer-controlled cutting machine. Is this the beginning of a second industrial revolution?

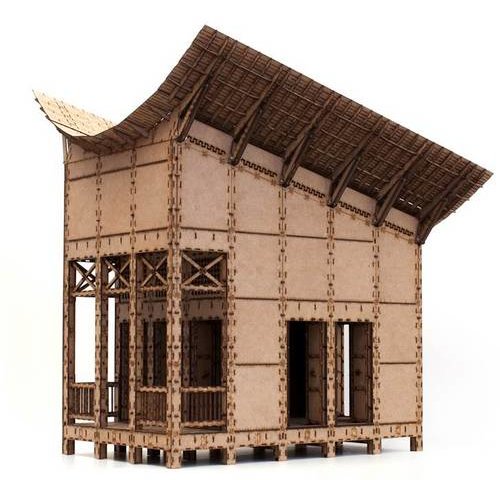

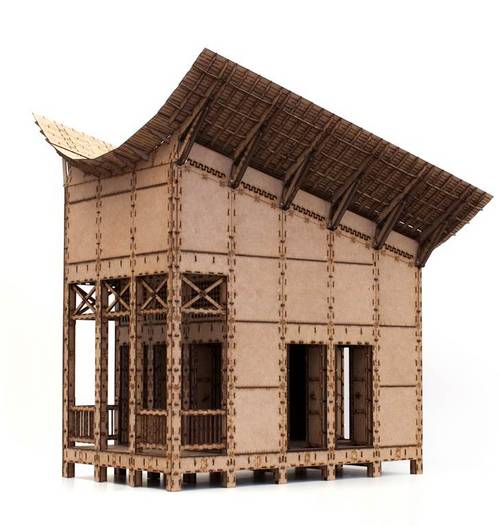

The house that he designed consists of no less than 2,484 parts. These fit seamlessly together (‘friction fit’). A CNC cutting machine can saw out parts to an accuracy of 0.01 millimetres, which makes it possible to build without screws and nails, in the same way that traditional Japanese builders do. “You simply slide it into place. In principle, anyone who is fairly good with their hands can build a house using this technology.”

The house, which is intended for an earthquake zone in Haiti, was designed entirely using a computer. The data can, therefore, be sent digitally. That means that it is possible to saw out the design anywhere in the world. For this reason, NGOs are extremely interested in the idea of Stoutjesdijk, who graduated cum laude, because they could use it to build cheap emergency housing. Stoutjesdijk: “You only need a man to press the start button of the cutting machine at the location.” It is also a very quick way of building: a CNC-controlled cutter can saw out all the parts of the house in approximately five hours, up to and including the doorknob. The largest size that the cutter can handle is 2.44 metres. It is also possible to use it to make dual layered constructions.

The model for the Haitian house (1:10 scale) was cut out of MDF. That is by no means weather-resistant, but it is possible to achieve better results with an innovative panel made from agricultural waste that Ecoboards, a company based in Delft, produces. Thanks to a nano coating, these panels last at least 15 years. The panel material can, in principle, be produced from agricultural waste anywhere in the world. Stoutjesdijk will soon be using it to build a music pavilion in Huis ter Heide. There are also plans to use it for houses in Rwanda. There may be even greater possibilities closer to home, as the interiors of shells can be designed using the computer. The cutting machine can produce a DIY home building kit quickly and accurately, which the occupant can put together himself/herself.