PerpetuAL

The metal windows and facades sector emits 175kton CO 2-eq annually, which is mainly caused by the extraction of aluminium from raw material. The production of recycled (secondary) aluminium consumes only 5% of the amount of energy. However, the circular chain is insufficiently closed: façade elements that are released from the demolition of existing buildings are largely exported as low-grade scrap. In order to contribute to the short-term climate objectives, the Dutch façade manufacturers want to develop a collective closed-loop system that offers room for new business models, from sustainable product to 'facade-as-a-service'.

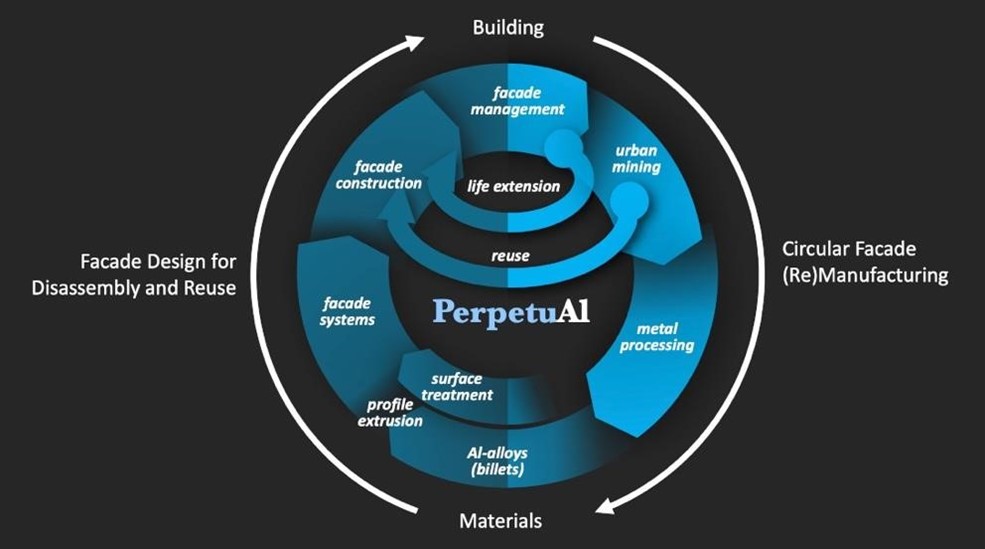

By 're-use', 'repair and remanufacture' and by increasing the proportion of recycle, up to 95% energy consumption can be avoided. And by changing technology and energy source, CO2 reduction is up to 100% possible. This requires simultaneous innovations at all links in the circular chain in the technological, process, business, and information technology areas.

The aim of the project is to test the feasibility of circular façade concepts and solutions to increase the percentage of second stream materials in the cycle, and to support this with an ICT platform for information exchange in the circular chain. PerpetuAl's mission is the development of technology and an (ICT) infrastructure that enables everlasting high-quality circular application of aluminium facades, façade products and materials, while reducing CO2 emissions to zero. Based on continuous realization, the ambition is to at least halve CO2 emissions within 7 years, to be completely CO2 neutral within 20 years.

Facts

| Funder: | RVO |

| Programme: | |

| Overall budget: | € |

| Grant amount: | € Contribution to TU Delft: € |

| Grant number: | |

| Role TU Delft: | Project partner |

| Project duration: | 1 year |

| TU Delft researchers: | Prof. Tillmann Klein |

Project partners

VMRG, RCS, Alkondor Hengelo, Schedelbouw Permasteelisa, Rollecate, Gevelbeer, Hydro building systems, Kawneer, New Horizon Urban Mining, Boverhoff, E-max, HKS, Schöck, ABT, Vereniging Industrieel Oppervlaktebehandelend, Hogeschool Utrecht, Bakker & Spees