New grab unloads vessels faster and smarter

There was plenty of reason to celebrate for transport technologist Dingena Schott and her team at TU Delft. Not only did they develop a design method for a new grab, but the grab, built by Nemag, complied with all of the predictions generated by the models, tests and simulations that they validated. ‘There is no precedent for this in the scientific literature. It’s definitely the crowning glory of our work,’ says Schott. This Dutch grab could potentially unload vessels in ports all over the world more efficiently and sustainably.

Every day, huge vessels from Brazil and Australia enter the port of Rotterdam with thousands of tons of iron ore, coal and other dry bulk. Here, crane operators ensure that the cargo is emptied quickly and efficiently, so that it can be stored or distributed to smaller vessels that then transport it via the Rhine to steel factories in Germany and Austria. To unload this kind of cargo, a crane operator has a variety of grabs to choose from, depending on the kind of dry bulk.

‘The question is: do they have the ideal grab for the product they want to unload?’ says Dingena Schott, who is doing research at the Department of Maritime and Transport Technology at the ME Faculty on new technologies for port-related transport logistics. ‘The most recent design for grabs is approximately fifty years old. Since that time, no fundamentally new designs have come onto the market.’ So does this mean vessels can be unloaded more quickly so that they can leave the port earlier to pick up the next load?

Schott thinks so. What’s more, the research that she and her team conducted has already led to an innovative grab that reduces the unloading time of a vessel by at least ten per cent. TU Delft developed the models, the insight and the design method for this, and worked together with grab manufacturer Nemag from Zierikzee, which created the new design. On 13 November, Nemag even received a prestigious award, a prize given by the International Bulk Journal for the most innovative technology for cargo handling.

At first sight, the new grab doesn’t seem that much different than existing grabs. All grabs have two shells with a hinge in the middle and a closing mechanism. ‘The aim is to get as much material as possible per grab,’ says Schott. ‘The amount is limited by the crane on the quay, which can only lift up to a certain weight. If you go for a really heavy grab, then it will of course penetrate deeper into the materials, but it can’t take as much per grab. So the ideal grab is as light as possible but can still dig itself in well. It’s kind of a trade-off between mass and force.’

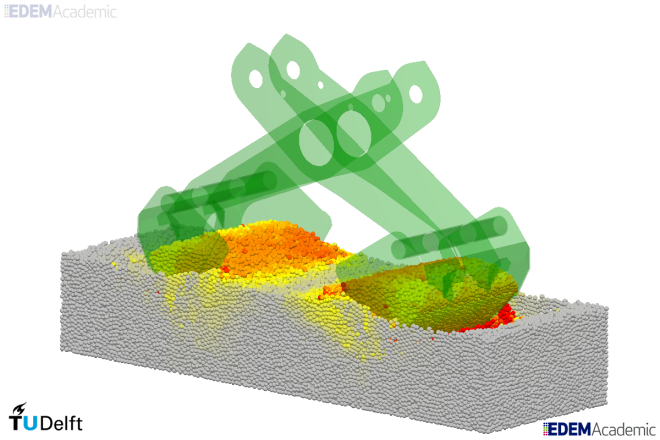

But where do you start when you want to improve a trusted grab in the conservative world of handling and storing bulk? ‘Since 2007, we have been using discrete element software as part of an innovative design method. Since the arrival of this technique, we have been able to understand for the first time exactly what happens when materials are grabbed. It makes it possible for us to model iron ore pellets as well as the grab, monitor their behaviour in a simulation when the pellets are grabbed, and thus determine whether the grab is being filled optimally. Initially we modelled and tested with an existing grab at Tata Steel in Ijmuiden in order to validate the model.’

Thanks to the software, Schott and her team can compute exactly how much force is needed to grab as many pellets of iron ore as possible. ‘In order to be able to move the grab you have to pull the cables at the top. Then the grab tries to close, but because of the resistance of the iron ore, it will become slower and slower. To maintain the same speed, you then have to pull harder on the cables,’ says Schott. To understand the dynamics of the grab together with the iron ore properly, she connected the dynamic grab model to the discrete element model. The difference between the existing and the new grab is in the overall design: both the new mechanism and the new shape of the shell ensure that the ratio between the forces exerted and the filling of the grab is optimised. That’s what ultimately makes it possible to unload a vessel in ten per cent less time.

It’s already a considerable improvement in efficiency. In addition to the productivity, which has increased by 10 per cent, the grab also weighs 15 per cent less. As a result, fewer scarce raw materials are needed. Moreover, vessels don’t stay in port as long waiting and unloading, which reduces emissions. But it could be even more effective.

Schott’s aim is to speed up the unloading process even more in the future by creating a dynamic grab capable of adapting itself. Moreover, it’s not just about the grab, but also the crane onto which the grab and cables are attached. ‘We only changed the grab design now, because we couldn’t change anything at the top of the crane yet,’ says Schott. ‘But actually we shouldn’t only be perfecting the grab, but also its interaction with the crane.’

Currently a PhD student is developing models for other kinds of bulk materials. The properties of a material, such as the shape of the particles, their texture and stiffness, mean that each material ‘behaves’ differently. This affects the flow inside the grab. Think, for example, of dry sand, which flows more easily than wet sand. ‘By analysing all kinds of substances, we can develop the grab even further. Ultimately, of course, we want a grab that performs optimally for all products and under all conditions.’

Read the press release by Nemag: 'Nemag wins the prestigious IBJ Award with the nemaX®