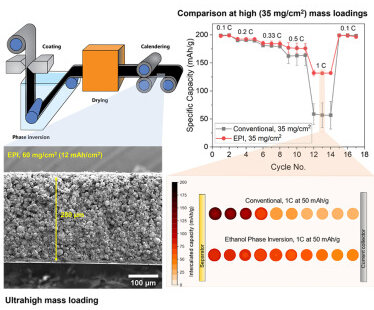

A phase inversion strategy enables thicker NMC811 electrodes for high-energy density Li-ion batteries.

Increasing the electrode thickness, thereby reducing the proportion of inactive cell components, is one way to achieve higher-energy-density lithium-ion batteries. However, when thicker electrodes are produced using the state-of-the-art slurry casting/drying procedure, this results in higher electronic and ionic overpotentials and/or mechanical failure induced by binder migration. Ethanol-induced phase inversion can effectively address these issues, as the inclusion of this processing step can produce robust, thick battery electrodes with improved electrochemical performance. These electrodes achieve higher available storage capacity per square centimeter and volume, using proven scalable technologies.

Pranav Karanth, Mark Weijers, Pierfrancesco Ombrini, Davide Ripepi, Frans Ooms e Fokko M. Mulder

A recent publication describing how these high capacity electrodes were obtained and tested electrochemically can be found in: A phase inversion strategy for low-tortuosity and ultrahigh-mass-loading nickel-rich layered oxide electrodes: Cell Reports Physical Science

H2020 project ‘SOLIDIFY’

Within the H2020 Solidify consortium comprised of, among others, IMEC, EMPA, Fraunhofer, VDL, Umicore, and TU Delft, research was performed to arrive at high energy density solid-state lithium-metal batteries. The phase inversion-based NMC-811 cathodes that were developed by researchers at MECS/ ChemE/ TNW have been selected for the demonstrators resulting from the project, where these electrodes are infiltrated with the solid electrolyte precursor to arrive at a solid cathode composite, and then combined with a thin solid-electrolyte separator and a lithium metal anode.