NWO Open Competition Grant for Hanieh Bazyar

Current membrane fabrication processes are not sustainable because they are energy-intensive and require hazardous solvents. We are all familiar with the concept of 3D printing as it has been used in various fields in the last decades. However, it couldn’t find its contribution yet to the big industry of polymeric membrane production. Hanieh Bazyar, Department of Process and Energy, received NWO Open Competition Grant for her research on next generation 3D printed separation membranes.

Open Competition ENW-XS project

In this project, Bazyar studies a novel 3D printing technology which can potentially overcome the limitations of the current 3D printing technology.

How does it work?

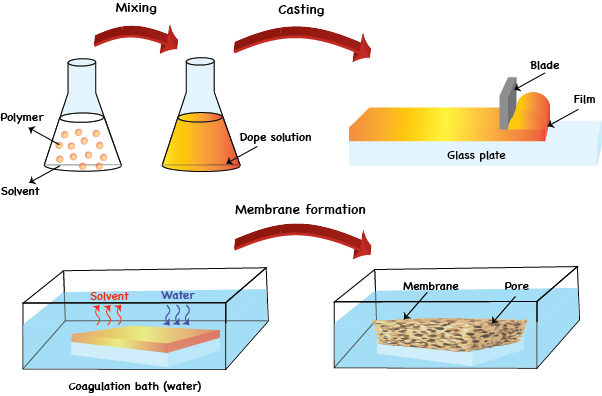

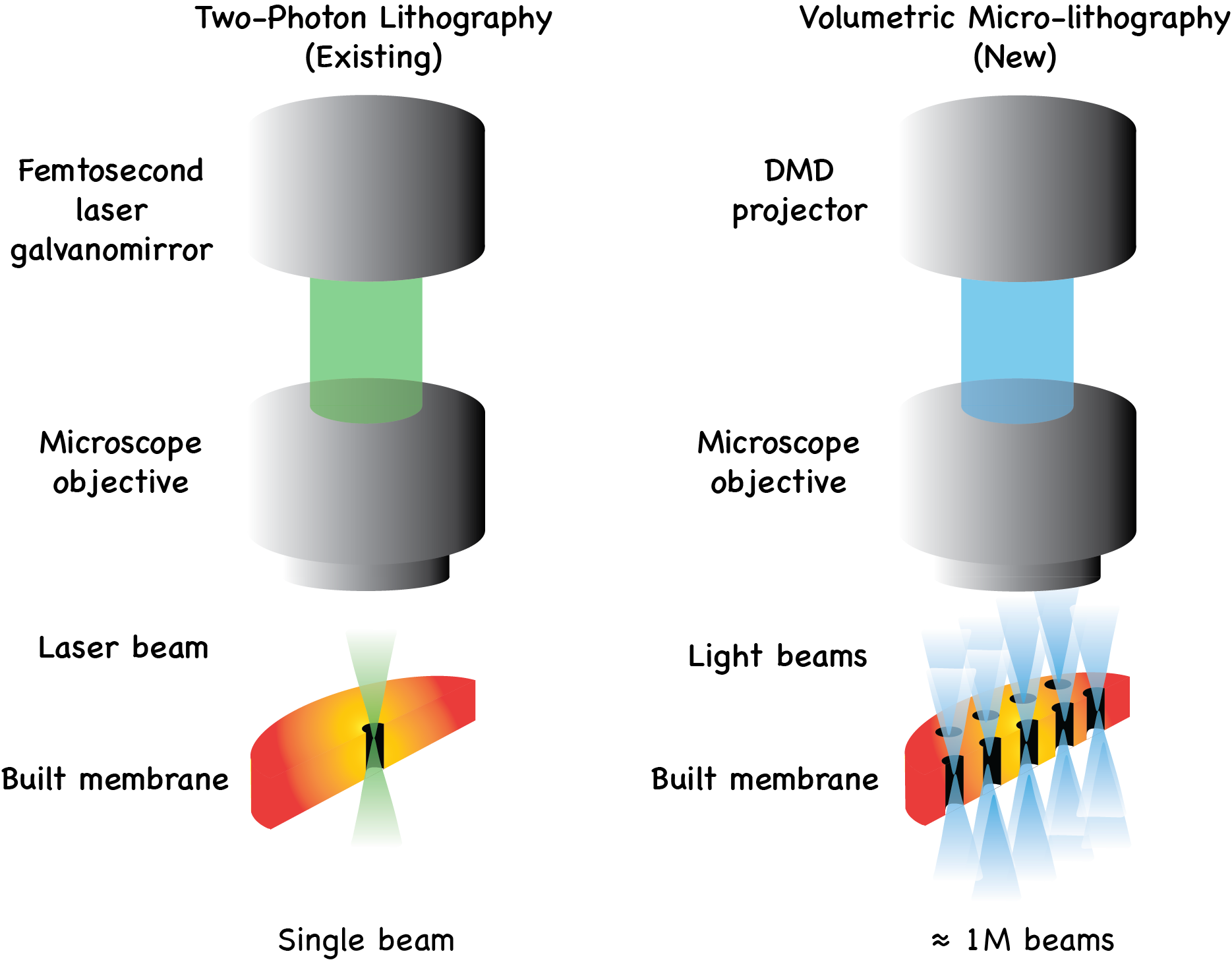

Current membrane fabrication processes are not sustainable as they are energy-intensive and require hazardous solvents (Figure 1 (a)). A new green method for membrane fabrication is 3D printing which eliminates extra fabrication steps, decreases waste production and CO2 emissions. Also, more control is provided on the design, shape and type of membranes. In this project I study the possibility of fabricating 3D-printed porous membranes with well-defined nano/micro-scale pore size, location and geometry using a novel 3D printing method (Figure 1 (b)). The proposed method can revolutionize membrane fabrication procedures leading to the development of novel membranes with high permeability and selectivity. The fabricated ultra/microfiltration membranes will be used for wastewater treatment applications.

Hanieh Bazyar

Figure 1.

(a) conventional method (non-solvent induced phase separation) for making polymeric porous membranes.

(b) comparison of the existing and our novel proposed technique for 3D printing porous membranes. In this technique, instead of a single light beam, million light beams are used to construct the nano/micro pores leading to a faster and less expensive 3D printing technique.

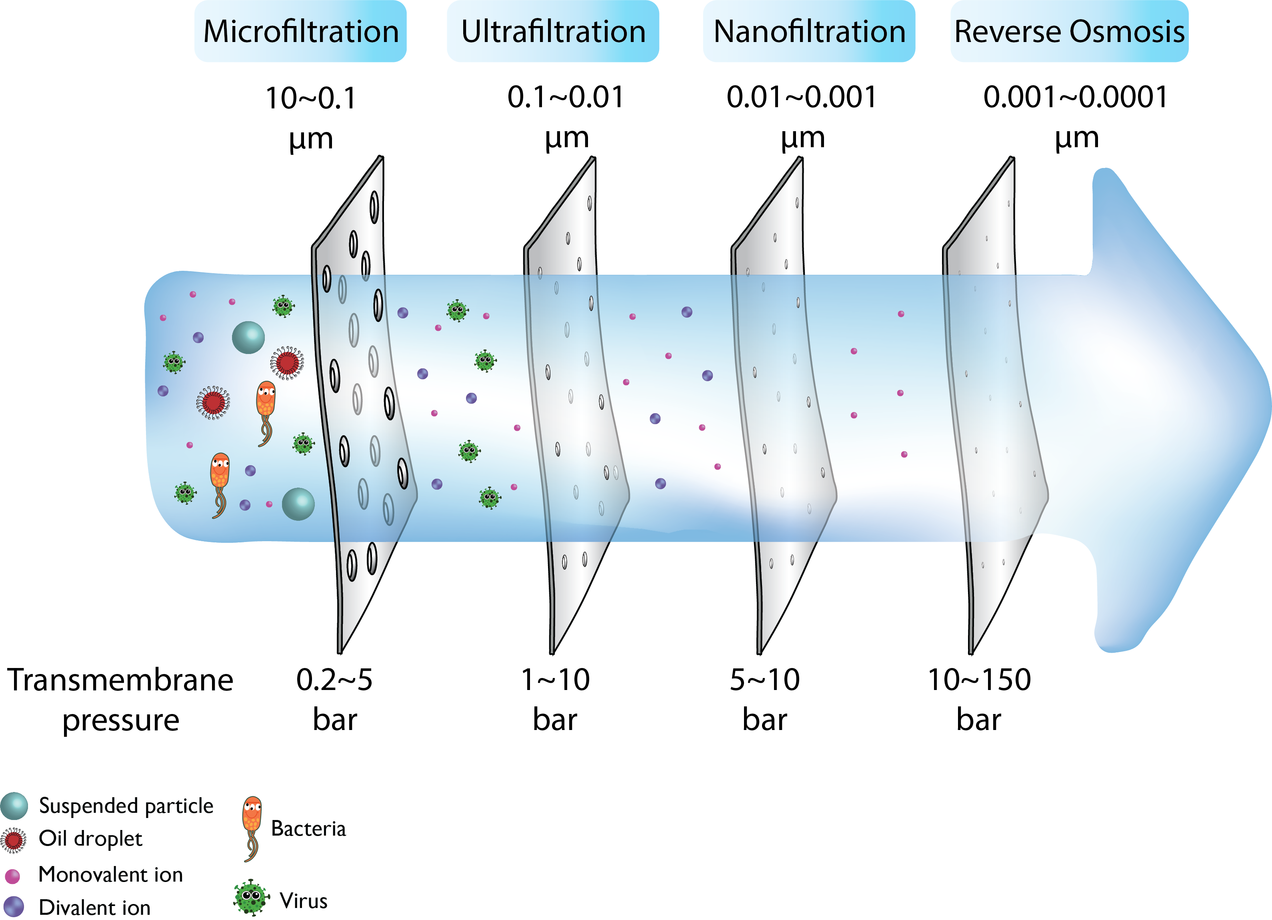

Hanieh Bazyar: "The main application of these membranes would be for wastewater treatment. We can make micro filtration membranes (for removal of bacteria, oil droplets, particles, etc.) as well as ultrafiltration membranes (for removal of smaller compounds/species such as proteins, viruses, etc.). With our 3D printing approach, we should be able to make micro filtration membranes as well as ultrafiltration membranes (the first two from left in the picture on the right)."

Hanieh Bazyar: "ENW-XS is a very good opportunity for the young researchers at the early stage of their career. It provides the possibility of studying high-risk ideas. The other advantage is that the results will serve as the basis for the bigger grants (ENW-M or ENW/XL)."

The Open Competiton ENW - XS Grant is explicitly about curiosity-driven, adventurous research and being able to quickly explore a promising idea.