LAMA

Laboratory for Additive Manufacturing in Architecture

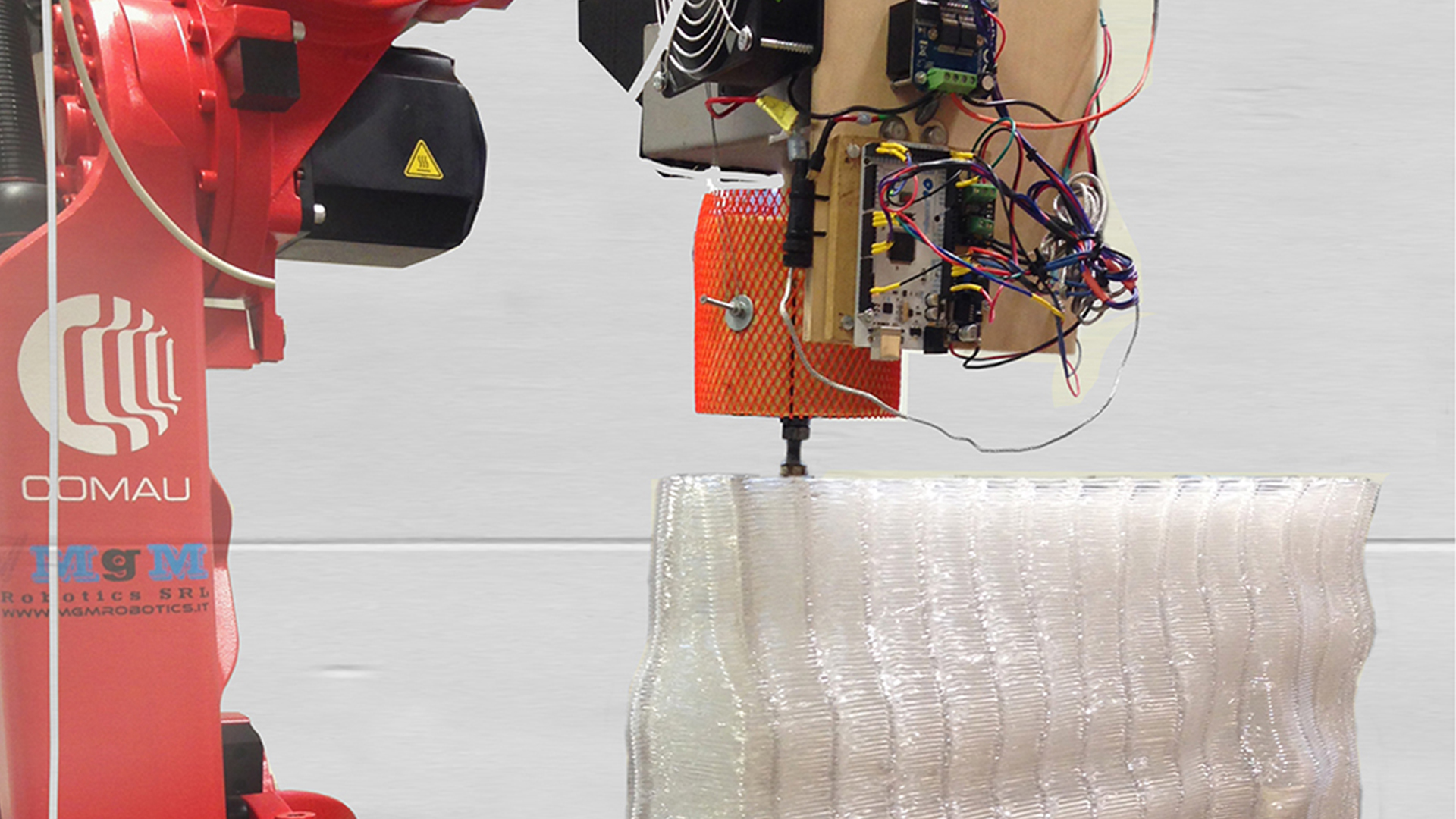

LAMA is an additive manufacturing lab which focusses on additive manufacturing applications in Architecture. The lab is research driven and combines integrated multi-disciplinary, optimization and rationalization design techniques and methods with the additive manufacturing process in support of the build of the resulting formal complex optimized and rationalized designs.

LAMA therefore integrates design methods and techniques with additive manufacturing techniques in an effort to effectively deal with resulting formal complexity. The resulting rationalization for manufacturing in the design process allows for optimal use of the manufacturing technique and will result in substantially reduced material use and machine time. With a strong emphasis on highly optimized integrated designs, the approach of LAMA is to find methods and techniques within the additive manufacturing process to minimize material use and substantially enhance the re-cyclability of the produced designs.

Approach

The lab allows the research of the rationalization and optimization process for AM in relation to the design process through prototyping. This not only in relation to the formal properties of the design but also in relation to its materialization and manufacturability of the design. It specially focusses on large scale competitive AM methods with recyclable and bio-based materials. The manufactured objects are tested in relation of their function to validate the design optimization and manufacturing process. Different sustainable materials are investigated to support the integrated design and manufacturing approach. Machine customization allows to research alternative AM approaches. LAMA is not only a place where you can build – in essence it is about generating knowledge on digital manufacturing.

Equipment

- 1- Comau NJ60

- 1- UR5

- 1- Xcel Leapfrog

- 1- Leapfrog HS

- 1- Leapfrog PR

- 1- Leapfrog Creatr

- 1- Big Builder

- 1- Prusa – testbed PR

- 3- Delta 3D printers PR

- Form1

- 1- Large scale printer PR

- Low noise compressor

- High flow extruder for Comau

- Extensive toolset for building and maintaining equipment

- 5 computers with simplify 3D software.

- 1- short throw beamer

- 2 tablets

- Substantial amount of spare parts and parts for new to build large 3D printers.