Help accelerate the development of ultra-lightweight structures for large aircraft

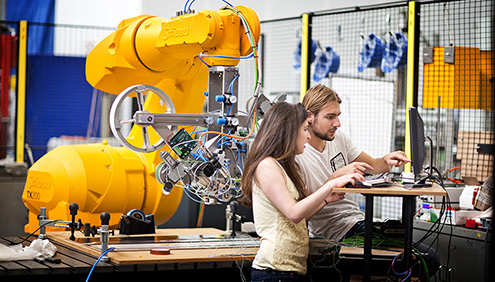

To drive climate neutrality in aviation, the development of ultra-efficient and lightweight aircraft is crucial. To this end, the Dutch government is funding a multi-year project geared to application-driven research into cutting-edge thermoplastic composites, structures and production technologies. To cover the wide range of research lines, we offer multiple PhD and postdoc positions. Would you like to work with leading manufacturers, airlines and researchers in the Dutch aviation industry and contribute to sustainable aviation?

| Covering the entire spectrum from material development and product design to production, certification, repair and reuse | Choose from a wide range of unique fundamental and experimental research lines and grow your career as a researcher | Conduct groundbreaking fundamental or experimental research and develop your academic career |

The project explained

In this project, the Dutch aviation industry and knowledge institutions collaborate to develop innovative thermoplastic composite technologies for parts, products and, ultimately, integrated structures. Using these technologies, structure weight is to be reduced by 15% to compensate the additional weight of hydrogen and hybrid-electric propulsion systems. The project covers the entire spectrum from material development and product design to production, certification, repair and reuse. In addition, the project aims to develop the factory of the future and smart structures.

In the first year, choices for product concepts and demonstration products will be made. The goal is to demonstrate new materials, production and product concepts for new aircraft platforms, and select promising technologies.

Lightweight Composites and Constructions

Watchtime 2:11s

PhD positions

Check out the unique research lines under these seven research fields:

-

- Durability, fatigue and damage tolerance

The relationships with static strength properties generally are understood, the relationships with long term behavior (durability and fatigue) and the damage tolerance are yet unknown, obstructing optimization of composites for long term performance. In this position you will help to change this situation. (Rene Alderliesten)

Start ASAP - Novel aerostructures with extreme morphing capabilities

You will develop design and manufacturing approaches for novel aerostructure with extreme morphing capabilities, overcoming established paradigms of stiffness and strength. (Clemens Dransfeld / Roeland de Breuker)

Start is mid/late 2024 - Gaussian curvature ultra-thin thermoplastic tapes.

You will develop applications for high Gaussian curvature ultra-thin thermoplastic tapes. (Daniel Peeters)

Start is mid/late 2024 - Repair of thermoplastic composite structures

You will develop additive manufacturing technologies for the repair of thermoplastic composite structures.(Kunal Masanai)

Start is mid/late 2025 - Life cycle inventories of thermoplastic composite production processes

You will develop life cycle inventories of thermoplastic composite production processes for a comparative evaluation against state-of-the-art benchmarks.(Benjamin Sprecher)

Start is mid/late 2025

- Durability, fatigue and damage tolerance

-

- Heat transfer during the heating phases of cut tapes

You will develop mesoscopic models for heat transfer during the heating phases of cut tapes to accelerate the process development with circular materials. (Sergio Turteltaub / Clemens Dransfeld)

Start ASAP - Microstructural features and macro-scale performance

You will contribute towards novel constitutive laws for the processing or use of thermoplastic composites by developing a deep understanding of microstructural features with respect to the fiber arrangement. You will experimentally identify these features and relate them to macro-scale performance. (Clemens Dransfeld)

Start ASAP - Constitutive laws for shaping cut tape materials

You will formulate constitutive laws for shaping cut tape materials, taking into account flow phenomena at the microscopic and mesoscale related to models for heat transfer. Additionally, you will help to develop and experimentally validate shaping equipment based on processing models developed. (Sergio Turteltaub / Clemens Dransfeld)

Start ASAP

- Heat transfer during the heating phases of cut tapes

-

- Next-generation sustainable thermoplastic composites

You will contribute to research on composites with new components for the next generation of sustainable thermoplastic composites for aerospace, such as strongly aligned natural fiber products for interior applications. (Baris Kumru)

Start ASAP

- Next-generation sustainable thermoplastic composites

-

- Advanced hybrid connections

You will develop predictive models for new interdiffusion and phase separation approaches to create customized interphases between thermoplastic and thermosetting polymer matrices for advanced hybrid connections.(Sid Kumar)

Start ASAP - Mapping the moulding conditions of thermoplastic composites

You will develop a numerical framework based on matrix formulations without meshes and advanced beam formulations for fibers to map the intricate molding conditions of thermoplastic composites.(Saullo Giovani Pereira Castro)

Start ASAP - 3D stress estimates / modelling a 3D RVE

Fibers in reinforced composites are not perfectly straight. In this work, you will dive into developing efficient 3D curved beam formulations that can provide accurate 3D stress estimations, apply suitable failure criterion and model their fracture. Contact among these beams and between beams and surrounding matrix region will also need to be handled effectively and efficiently. The final objective is to be able to model a 3D RVE of fiber-reinforced composites with realistic statistical representation of the fiber curvatures. (Boyang Chen)

Start ASAP - Predicting and reducing thickness variations

You will focus on the way gaps and overlaps build up during the manufacturing process. The total thickness of the manufactured part and the variation of it will play a big role when trying to assemble multiple parts together, either with adhesive bonding, welding or riveting. This work will try to come up with a predictive model of realistic thickness variations and possibly methods to reduce this variation. (Daniel Peeters)

Start ASAP - Process to assemble discontinuous composite structures

You will develop a computer vision-guided process to assemble discontinuous composite structures from cutting waste. (Kunal Masania)

Start ASAP

- Advanced hybrid connections

-

- Dissipative heating of embedded superparamagnetic iron oxide particles

You will develop a new inductive heating method based on dissipative heating of embedded superparamagnetic iron oxide particles. (Laura Rossi)

Start ASAP - Manufacturing parameters geared to structural integrity

To contribute for the aircraft of the future, this research will focus on the manufacturing parameters such as surface treatment (such as laser, plasma and UV) and interface morphology, with the aim to improve the structural integrity of those bi-material interfaces either by chemical interaction or mechanical interlocking. (Sofia Teixeira De Freitas)

Start ASAP - Analysis and test methods for certification

You will develop analysis and test methods related to crucial certification aspects of composite welded constructions. The relationship between process parameters in the production process and mechanical properties, as well as structural behavior, will play a significant role.(Sergio Turteltaub)

Start ASAP

- Dissipative heating of embedded superparamagnetic iron oxide particles

-

- In-line and non-invasive inspection technologies

You will develop an in-line and non-invasive inspection technologies for the tape laying process with an unprecedented spatial resolution. (Roger Groves)

Start is mid/late 2024 - Embedded sensor and monitoring techniques

You will develop embedded sensor and monitoring techniques to evaluate thermomechanical loads and crack formation in cryogenic conditions.(Nan Yue)

Start is mid/late 2024

- In-line and non-invasive inspection technologies

-

- Digital thread for composites manufacturing

You will develop a digital thread for composites manufacturing within Industry 4.0 (Nathan Eskue)

Start is mid/late 2024 - Drone and Extended Reality Technologies for Industry 5.0

As of today, industry 4.0 is already around us. Digitalisation, cloud network, artificial intelligence and the internet-of-things (IoT) are tools used in all sectors to automate production lines, lower resources, waste and costs while boosting yields. The future brings however an even better prospective where disruptive technologies will enable digital infrastructure, smart cities, and human-robot ecosystems.

We propose the introduction of drones inside the factory to perform contact-based tasks and diagnostics of large infrastructure. Within this project, we aim to extend the capabilities of drones to also perform grasping and manipulation tasks inside the factory, aiding human workers in maintenance and assembly tasks by incorporating extended reality technologies (XR). (Salua Hamaza)

Start mid/late 2024 - Large scale grippers with embedded intelligence for inspection

Large scale grippers with embedded intelligence for inspection in the factory of the future. This project is about design and manufacturing of gripper with embedded sensing functionalities for inspection of manufactured parts. The gripper will be flexible to be able to adapt to parts with different shape. Due to embedded sensing functions during handling, the gripper can characterize properties of the manufactured part during transport. Embedded sensing will be part of the contact surface of the gripper as well as of the soft body. The body will be designed as mechanically intelligent structure from multiple smart materials in patterned configuration and will be manufactured using additive manufacturing. Smart materials, like piezoelectric or shape memory materials will be used for tailored functionality. Design, numerical modeling and additive manufacturing will be part of this project.(Jovana Jovanova)

- Digital thread for composites manufacturing

Postdoc positions

Check out the unique research lines under these two research fields

-

- Production of ultra-thin composites

You will develop novel production technologies to manufacture ultra-thin thermoplastic unidirectional carbon fibre reinforced tapes. In addition, you will deconvolute the relationship between processing parameters and microstructural characteristics and performance.(Clemens Dransfeld)

Start ASAP - Performance of formed chopped tape composites

You will develop alignment methods to enhance the performance of formed chopped tape composites on larger structures.(Clemens Dransfeld / Reza Sabzevari)

Start is mid/late 2024

- Production of ultra-thin composites

Inspired?

Check out the job posting for the requirements and employee benefits. If you think you’re a match, we’d like to meet you. To apply, please complete the application form, and upload your motivation letter and detailed CV. Please state your research line(s) of choice in your cover letter and application form.

Do you have any questions? Talk to us

If you would like more information about these roles and our research lines, please contact please contact Martin Kampinga, Programme Manager, via M.Kampinga@tudelft.nl.